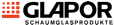

Unused flat roof, Underground concrete, sealed with bitumen, freely weathered

- Top layer of the seal

- Bottom layer of the seal

- GLAPOR flex hot bitumen

- GLAPOR foam glass boards

- GLAPOR flex hot bitumen

- Separation layer over wooden formwork

- wood construction

Description of the application

The GLAPOR flat roof on a wooden substructure is a compact and under flow secured bonded flat roof construction.

The thermal insulation is installed free of thermal bridges using GLAPOR flex hot bitumen or GLAPOR k-2k cold glue on the entire substructure.

The sealing system conforms to the legal and normative regulations for the respective intended use.

The minimum roof pitch of the flat roof construction of 2.0% should be respected. The GLAPOR tapered system has different slopes available.

To avoid concentrated drainage GLAPOR roof riders are available in different versions.

Planning notes / Execution notes

A vapor barrier is not required when using GLAPOR cellular glass insulation because GLAPOR cellular glass boards are vapor-tight.

The underground should be level, gem. DIN 18 202, designed to be load bearing and dry and free from residues (oil, grease, etc).

10 kN / m² can be assumed without proof for the wind resistance of fully glued roof systems with GLAPOR foam glass and GLAPOR flex hot bitumen.

Fire protection “Hard roofing” according to DIN 4102-7 – Cellular glass panels belong to building material class A1. The thermal insulation is not flammable. For the component “roof”, the state building regulations require, in addition to the classification in a building material class (A1) usually a so-called “hard roofing”. This is to ensure that the roof structures are resistant to spreading fire and radiant heat. For the manufacturers of waterproofing systems, these tests with the different seals are available.

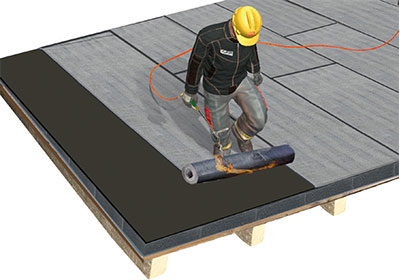

Installation instruction

Clean the wooden roof surface and install a suitable separating layer on the wooden surface. Nail off according to wind load requirements.

For example: nail bitumen sheet with overlap.

Pour GLAPOR flex hot bitumen. Consumption 5-8 kg / m² depending on the evennes of the underground.

Pour GLAPOR flex hot bitumen, Immerse the insulation boards with two sides in the adhesive.

Insert diagonally so that the longitudinal and transverse joints are filled with bitumen.

For a short time, secure the insulation board against movement.

Pour GLAPOR flex hot bitumen paste and spread with a rubber spatula on the cellular glass surface as a cell-filling top coat.

Consumption about 2 kg / sqm.

Install a two-layer, bituminous waterproofing over the entire surface.

Torch first and second layer.

Note: Welding the waterproofing membranes directly onto cellular glass boards - without top coat - is not possible!